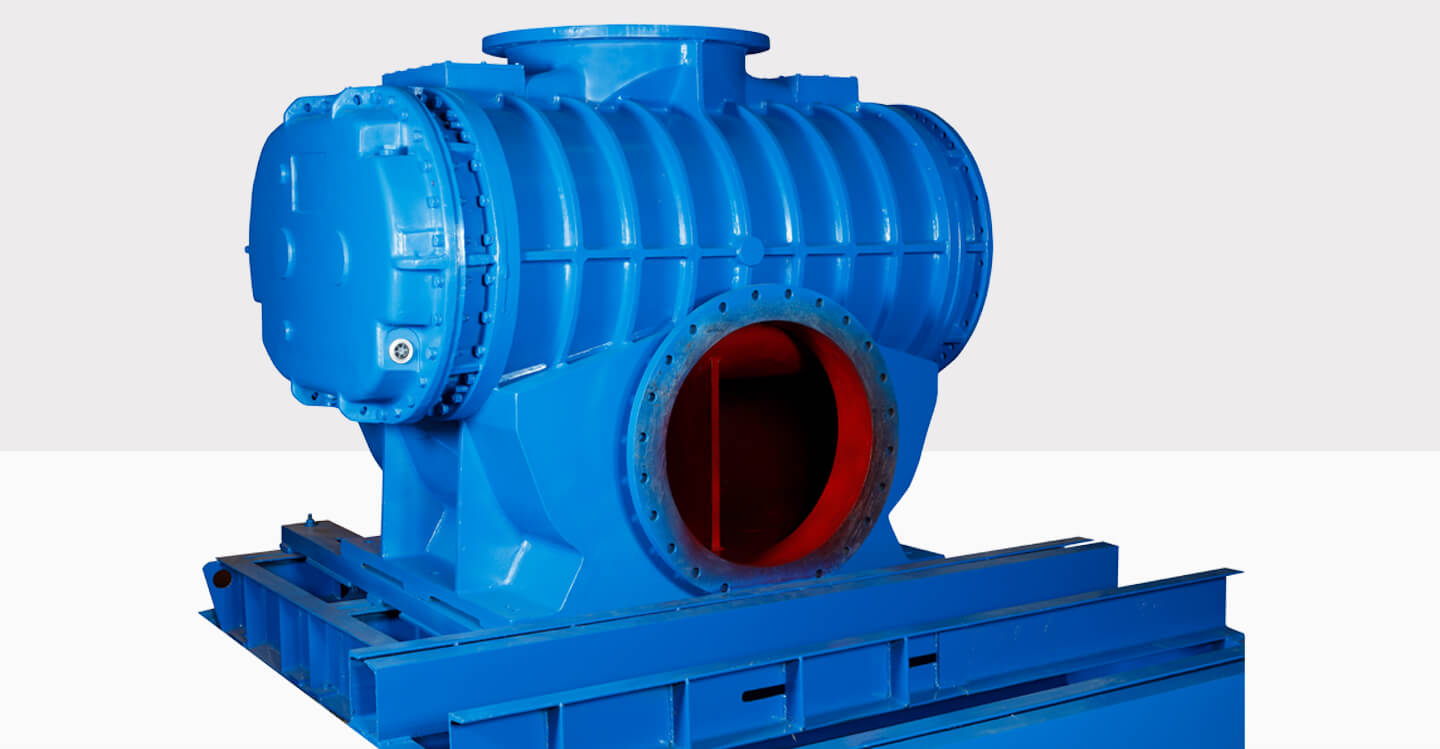

Kay- 2KHC Series

ROTARY POSITIVE DISPLACEMENT TWIN LOBE COMPRESSORS

Salient Features:

This series covers the roots blowers from 1620 AC to 2266 AC.

2KHC series is the high capacity series. In 2KHC 2 stands for twin lobe roots blower, K for Kay and HC for high capacity.

Series covers only air cooled blowers with forced lubrication systems.

Capacity for 2KHC series ranges from 8000 m3/hr to 64000 m3/hr with pressure application from 1000 mmwg (0.1 kg/cm2) to 10000 mmwg (1 kg/cm2).

5 bearing with shaft roller bearing is well suited for V-belt as well as direct coupled drive.

2KHC series is the series of high capacity roots blowers and is applicable where large quantity of air is required with pressure. (Up to 1 kg/cm2).

Casings are newly designed one piece style, including extra deep ring section for greater rigidity under vacuum of pressure service. In many of the longer cases inspection ports are provided to give access for internal and clearance check.

Impellers and Shaft are made of SG iron and separate forged shaft duly precision machined is shrink fitted accurately machined for close tolerance operation S . G Iron / Forged steel material is used for better strength and longer life.

Steel shafts are made from alloy steel [BS : 970 series of steel] toughened to resist bending and for imparting high fatigue life. The shrink fit through the impeller eliminates torsional deflection and permits increased pressure ratings and greater efficiencies.

Impellers are made of SG iron and accurately machined for close tolerance operation, dynamically balanced for smooth running and lower bearing loads.

Lubrication of the basic units in the series 18” to 22” feature trouble free splash lubrication of all bearing and timing gears. Generous size sumps are located in the gear cover and drive cover. A full force feed lubrication system is available as an option. The system features and automatically reversible, shaft mounted pump, with an oil strainer and by-pass relief valve. Oil is delivered to all bearings and to the timing gears from a single large sump in the gear cover.